Lihlahisoa

Li-steel tsa tšepe tsa tšepe li-Philippips flat hlooho

Tlhaloso ea Sehlahisoa

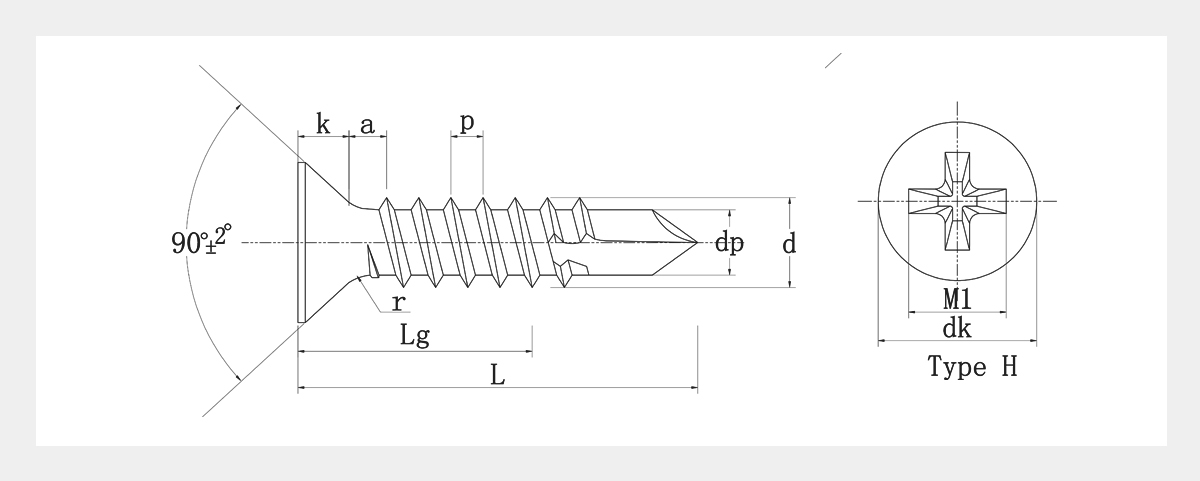

| Lebitso la Product | Li-steel tsa tšepe tsa tšepe li-Philippips flat hlooho |

| Lintho tse bonahalang | Entsoe ka tšepe e se nang male, likhomphutha tsena e na le lik'hemik'hale tse ntle tsa lik'hemik'hale 'me li ka ba makenete e bonolo. |

| Mofuta oa hlooho | Hlooho ea likhoho |

| Bolelele | E lekantsoe ho tloha holimo holimo |

| Kopo | Ha ba sebelisoe ka tšepe ea aluminium. Tsohle li hlolloa ka tlasa hlooho bakeng sa ho sebelisoa ka masoba a maraba. Screws e kenella ho kenella hare 0.025 "le tšepe ea pampiri e tšesaane. |

| Tloaelo | Screws e kopanang le О B18.6.3 kapa Din 7504-o ka Melao ea Boholo. |

Likopo tsa likhoele tsa tšepe tsa tšepe tse tsoang hloohong tsa tšepe

Li-scelers tsa tšepe tse se nang thuso li na le li-sceleder tse fapaneng li sebelisoang likopanong tse fapaneng ka lebaka la ho tšoarella ha tsona, li-corrosation tsa bona. Ho khona ho honohela bokhoni ba bona ho felisa tlhokahalo ea nako ea ho cheka, ho boloka nako le ho netefatsa hore ka tsela e fapaneng.

1. Ha ho hahoe le merero ea kaho

Marulelo: Sireithi e sireletsehileng ea tšepe, li-panels le lisebelisoa tse ling marulelong tse eang ho meaho.

Foreiming: Liforomo tsa mafora kapa liforeimi tsa tšepe le ho nepahala le ho qeta nako e boreleli.

Ho lahla: ho fana ka pheletso e hloekileng, e bataletseng bakeng sa merero ea kantle ho kantle.

2. Ho etsa mesebetsi ea tšepe

Khothatso ea tšepe ea tšepe: E loketseng likarolo tse kopaneng tsa tšepe, lisebelisoa tsa indasteri kapa tlhahiso ea likoloi.

Mekhoa ea aluminium: e sebelisoe bakeng sa ho bokana litsie tsa Aluminium ntle le tšebelisano le thunthung.

3. Ho na le mapolanka

Likhokahano tsa tšepe tse nang le patsi: ho kopanya lehong le sireletsehileng ho mehala kapa liforeimi.

Kopano ea The ea Thepa: Theha sehlopha sa litsebi, se fella ka setotsoana kahong ea thepa ea thepa.

4. Likopo tsa leoatle le tsa kantle

Likepe le likepe: likarolo tse sireletsehileng libakeng tsa metsing moo likhara tsa sirapo e senyehileng li bohlokoa.

Terata le fatše: ho tiisa lipelaelo tsa kantle tse pepesitsoeng ke boemo ba leholimo le mongobo.

5. Mechine ea indasteri le lisebelisoa

Mehala ea Kopano: Bokella mechini le lithibelo tse hlokang ho etsahala le ho tšoarella.

Litokiso le Tlhokomelo: Pheta bahahlauli ba apereng le li-crarod

6. Hvac le litlatsetso tsa motlakase

Qoba: li-ducts tsa moea le liforeimi tsa tšepe li sireletsehile.

Koloi: Hokela li-genels le likarolo tse sebetsang hantle.

| Setsi sa Thread | St2.9 | St3.5 | St4.2 | St4.8 | St5.5 | St6.3 | ||

| P | Pitch | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| a | Max | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| dk | Max | 5.5 | 7.3 | 8.4 | 9.3 | 10.3 | 11.3 | |

| min | 5.2 | 6.9 | 8 | 8.9 | 9.9 | 10.9 | ||

| k | Max | 1.7 | 2.35 | 2.6 | 2.8 | 3 | 3.15 | |

| r | Max | 1.2 | 1.4 | 1.6 | 2 | 2.2 | 2.4 | |

| Socoke No. | 1 | 2 | 2 | 2 | 3 | 3 | ||

| M1 | 3.2 | 4.4 | 4.6 | 5.2 | 6.6 | 6.8 | ||

| M2 | 3.2 | 4.3 | 4.6 | 5.1 | 6.5 | 6.8 | ||

| dp | 2.3 | 2.8 | 3.6 | 4.1 | 4.8 | 5.8 | ||

| Range (botenya) | 0.7 ~ 1.9 | 0.7 ~ 2.25 | 1.75 ~ 3 | 1.75 ~ 4.4 | 1.75 ~ 5.25 | 2 ~ 6 | ||